Ten questions about iiRDS

Two founding members of the iiRDS Consortium explain the importance and potential of iiRDS and its integration at Endress+Hauser. An interview with Thomas Ziesing from Endress+Hauser and iiRDS consultant Ulrike Parson from parson.

Interview: Susanne Lohmüller

This interview was first published in the November 2024 issue of tcworld magazine.

Thomas Ziesing worked as a media documentalist in the chemical-pharmaceutical industry until joining Endress+Hauser more than 25 years ago. He was involved in several projects in the online sector before taking over responsibility for the translation management process and the coordination of the technical editing departments of the Product Centers at Endress+Hauser Consult AG.

Ulrike Parson is the founder and CEO of parson AG, a service provider for technical communication. Her areas of expertise are consulting for content strategy, digitalization, and intelligent information. She is a member of the iiRDS Steering Committee.

How did you come across iiRDS?

Thomas Ziesing (Endress+Hauser): tekom brought the topic to our attention. We found the approach and possibilities of iiRDS so interesting , we joined the Consortium as a founding member in 2018.

Since then, we have been working in the Consortium on the further development of iiRDS.

Why did you choose iiRDS?

Thomas Ziesing: We see the greatest potential in the openness and expandability of iiRDS. As one of the leading providers of measurement instrumentation, services, and solutions for industrial process engineering, Endress+Hauser has gained sufficient experience in the past with standards for describing and classifying our products, e.g. NE100, ECLASS. In doing so, we have often encountered the problem that certain aspects and features and, in some cases, entire device types cannot be mapped or cannot be mapped completely.

In addition, many of these standards are tailored to the requirements or needs of a specific industry. However, as Endress+Hauser is active in a wide range of industries, this often presents us with problems and generates increased effort.

We see iiRDS as an opportunity to map our information comprehensively and holistically. In addition, iiRDS is combinable with other industry standards such as ECLASS, and the consortium actively cooperates with such industry standards. This makes it possible to map all our metadata in a single model and thus optimize our processes. Efforts towards international standardization as a process model for the exchange of information also benefit our activities regarding digitalization and Industry 4.0.

Ulrike Parson (parson): iiRDS offers a standardized information model for technical documentation that is ideally suited as a blueprint for company-specific metadata models, regardless of the technical implementation. And this knowledge can be used by any company free of charge, as iiRDS is an open-source standard.

For which products do you use iiRDS?

Thomas Ziesing: We are currently working on a project in which we are completely redesigning the authoring, management, and delivery of technical communication information. This information is authored as topic-oriented information units and stored in a comprehensive information model. These information units are then linked to the contexts for which they are valid via a graph-based product model. The aim is to be able to generate order code-specific documentation in the future and to make these information units available to other applications in a context-oriented manner.

iiRDS serves both, as an ontology for structuring and classifying the content and as the delivery format for making the content available.

How do you use iiRDS in technical writing?

Thomas Ziesing: As part of the project mentioned earlier, the content of the technical documentation is created in information units based on topics. These information units are DITA-based and are automatically enriched with the metadata that they receive through their mapping to the information model and product model. As iiRDS is the underlying ontology, the metadata is based on it.

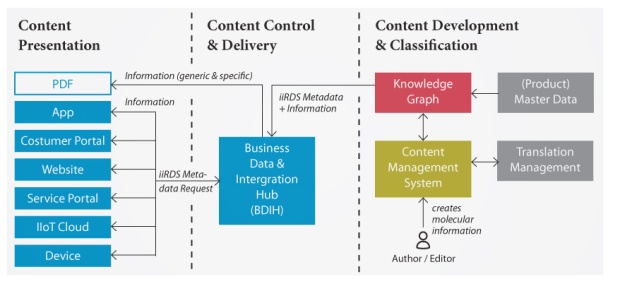

In the future, the information units will not only be made available in information products such as operating instructions but will also be addressed and delivered individually and specifically via the metadata in order to be used, for example, in an app or website. iiRDS will serve as the transfer format: The information units are transferred to a content delivery portal in the form of iiRDS packages. End users and apps can find the information from the portal via metadata and retrieve it for further use.

Have you brought in external support?

Thomas Ziesing: We called in parson AG for technical and information architecture consulting in this project. Like Endress+Hauser, parson is a member of the iiRDS Consortium and brings a great deal of expertise to this area as well as to DITA, which helps us a lot.

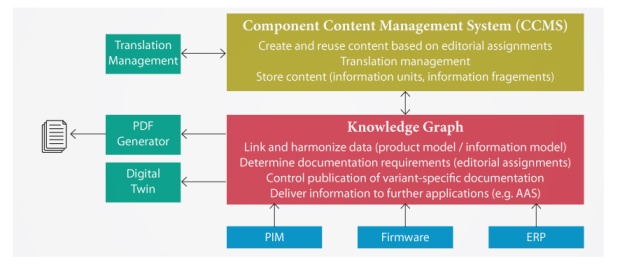

We are also working together with Empolis, another iiRDS Consortium member, as a technical partner. Here, we use their Knowledge Graph component for modeling product information and documentation metadata as well as linking CCMS content with product data.

Which other departments are involved in the implementation of iiRDS?

Thomas Ziesing: The project in technical communication is a pilot with which we want to test and demonstrate the possibilities of iiRDS. In principle, it is feasible to extend this concept to other types of information, and we are planning to do so.

Ulrike Parson: In our iiRDS project, information from different groups and sources is already merged: The product data comes from different systems such as a PIM and a software configuration system, the information model is maintained by the technical writing groups, and product management is responsible for ordering options for the products. Thus, the project also has the major task of harmonizing data from different sources.

Source: Ulrike Parson and Thomas Ziesing

Thomas Ziesing: There is great interest in this harmonized product data and documentation content, which can be compiled to match the order code, especially in the area of digitalization activities. On the one hand, we are planning to integrate this content into our own applications and, on the other, to deliver the technical documentation in an administration shell for the digital twin. The corresponding submodel "Intelligent Information for Use" is also based on the iiRDS concept. 1

Do you involve your suppliers?

Thomas Ziesing: We are already talking to one of our customers, a plant manufacturer, who is very interested in our concept and would like to integrate iiRDS packages into its engineering processes. They see considerable potential for simplifying and optimizing their processes.

I expect that such collaborations will increase as soon as the project is completed and we can make the content of the technical documentation available in the form of topic-oriented information units.

How have processes in technical writing changed with the introduction of iiRDS?

Thomas Ziesing: The implementation of the project will fundamentally change the processes in technical writing. The document-oriented authoring and management of content will be replaced by topic-oriented authoring and management based on an information model and product models.

Technical writers will no longer have to work in the context of documents but based on editorial assignments. In an editorial assignment, the content for a specific subject area is compiled according to the product variant, e.g., for the commissioning of the product. The content is compiled based on the data and relations in the Knowledge Graph, which manages the product and information models. Existing information units are automatically determined based on the assigned metadata, and missing information units are created. The structures of these information units are DITA-based.

Once the technical writer completes the editorial assignment and the content is approved, the information units are translated and published. As a result, they are available in all necessary languages for use in a content delivery portal.

Compiling and publishing information products, such as operating instructions or data sheets, are independent of the authoring processes. Information products are generated on demand. Mechanisms such as an automatic completeness check ensure that all the necessary information for an information product is available. The information products are equipped with all the required metadata and can be published in various output formats. We hope that this will significantly speed up the authoring process, as editorial assignments can be started earlier and in a more focused manner. The higher granularity of the information units will give us greater flexibility in terms of use, allowing us to use content in different information products and contexts. This has taken us to the point where we will be able to deliver order code-specific documentation and information in this way. It also prepares the technical writing team for the growing requirements associated with digitalization and enables them to contribute to formats such as the administration shell or the digital twin.

What future benefits do you expect from iiRDS?

Thomas Ziesing: As already mentioned, iiRDS serves as an ontology for structuring and classifying content and will be the delivery format for making it available. The openness and individual expandability allow us to classify the information on our devices and products without major restrictions.

The search and delivery options also meet our requirements. This makes it easier for us to provide technical documentation information for different applications. We also see the cooperation and coordination with other committees such as ECLASS or VDI 2770 as an advantage, as this will considerably simplify the exchange between different systems.

Ulrike Parson: Using standards such as iiRDS and DITA makes the new documentation concept less dependent on the technical implementation in a specific content management system. At the same time, we are using the knowledge contained in these standards and do not have to develop all concepts from scratch. We can use future additions to the standards for our project.

Where do you see potential for improvement in iiRDS?

Ulrike Parson: For a long time, one area for improvement was the lack of a request interface for iiRDS content. However, the Consortium is currently working on this, and we are hoping to be able to use this API for future delivery of Endress+Hauser content2. Also, iiRDS deliberately does not map the product dimension, e.g., product functions, product features, and product variants. iiRDS is an information model, not a product data standard. However, this must be taken into account in a project such as Endress+Hauser's – the product model must be developed specifically for the company and linked to iiRDS.

References

1 https://landkarte.interopera.de/wp-content/uploads/2023/08/Submodel-Specification-Document_Intelligent-Information-for-Use.pdf

2 The API for querying and retrieving iiRDS RDF resources is now available.

iiRDS RequestAPI

The specification for the request interface has now been published by the iiRDS Consortium on their website (iirds.org). At the tcworld conference from November 5 to 7 in Stuttgart, this year's iiRDS developments will be presented, such as the plugin for DITA-OT, the request API and the associated mock API to be developed in the fall. There will also be presentations on the iiRDS pilot projects.

iirds.org

tcworldconference.tekom.de

About Endress+Hauser

Endress+Hauser is a global provider of measuring instruments, services, and solutions for industrial process engineering. The company offers process solutions for flow, level, pressure and temperature measurement, analytical measurement, data logging and digital communication, and optimizing processes in terms of economic efficiency, safety, and environmental impact. Customers operate in a wide range of industries, such as chemicals, energy and power plants, basic materials, metals & mining, food, life sciences, oil and gas, and water/wastewater.

About the technical writing team

More than 40 technical writers work across technical editorial offices in five Product Centers. They currently use COSIMA Enterprise to create operating instructions, short instructions, safety instructions, installation instructions, and other documents, primarily in the form of print documents, which are made available in up to 30 languages.